Revealing the Diverse Series Of Welding Services and Their Advantages

As industries continue to progress and demand precision in their manufacturing processes, the relevance of welding services has actually become significantly noticable. From the flexibility of arc welding to the efficiency of MIG welding, and the elaborate work achieved through TIG welding to the accuracy of laser welding, the array of welding strategies available is substantial. Each approach brings its own collection of advantages and applications, accommodating a wide variety of requirements across various industries. Understanding these diverse welding services and their advantages can provide valuable insights right into enhancing fabrication processes and accomplishing superior results.

Types of Welding Services

One usual type is MIG welding, likewise recognized as Gas Steel Arc Welding (GMAW), which utilizes a cord electrode to join metals with each other. An additional widely used technique is TIG welding, or Gas Tungsten Arc Welding (GTAW), which uses a non-consumable tungsten electrode to produce a tidy and exact weld.

Additionally, there is Stick welding, or Secured Metal Arc Welding (SMAW), which is understood for its simpleness and efficiency, especially in outside or windy conditions. There is Flux-Cored Arc Welding (FCAW), which is a flexible process appropriate for thick products and can be utilized in both automated and semi-automatic applications.

Advantages of Arc Welding

Arc welding uses a multitude of advantages that accommodate numerous commercial needs and needs. Among the main advantages of arc welding is its convenience. Welding Inspection Service. This welding approach can be made use of on a variety of steels and alloys, making it a prominent option for industries functioning with diverse materials. Additionally, arc welding is known for its high welding rates, which can significantly raise efficiency in manufacturing procedures. The process is also fairly easy to automate, lowering labor prices and enhancing general performance.

Another secret benefit of arc welding is its capacity to produce strong and resilient welds. The warm generated during the process assists to produce a metallurgical bond in between the base steels, resulting in welds that are able to withstand high levels of stress and anxiety and pressure. Arc welding additionally creates tidy and exact welds, lowering the need for extra completing work. Overall, the benefits of arc welding make it a valuable device for different industries aiming to accomplish top quality welds effectively.

Benefits of MIG Welding

With a concentrate on performance and resilience in welding processes, MIG welding provides a distinct collection of benefits that complement the flexibility and strength discovered in arc welding. MIG welding, or Gas Metal Arc Welding (GMAW), is understood for its speed and convenience of usage. The procedure involves feeding a cord electrode with a welding gun, which is after that melted and made use of to join the base products with each other. Among the crucial benefits of MIG welding is its high welding rates, making it a recommended choice for tasks that call for fast turnaround times.

Additionally, MIG welding generates clean welds with minimal splatter, minimizing the requirement for comprehensive cleaning after the welding procedure. The versatility of MIG welding enables welding a click for more info wide variety of materials, consisting of aluminum, stainless-steel, and moderate steel. This adaptability makes MIG welding ideal for different industries, from vehicle to construction.

Moreover, MIG welding is recognized for its high deposition prices, meaning even more material can be transferred in a much shorter amount of time contrasted to various other welding processes. This leads to increased efficiency and cost-effectiveness for projects that need huge volumes of welds. Overall, the benefits of MIG welding make it an important strategy for accomplishing long lasting and effective welds throughout various applications.

Discovering TIG Welding Benefits

TIG welding, additionally recognized as Gas Tungsten Arc Welding (GTAW), supplies an unique set of advantages that provide to accuracy and control in welding applications. One of the primary advantages of TIG welding is its capacity to produce top quality, tidy welds without the need for filler product.

Additionally, TIG welding can be utilized on a vast array of steels, including stainless-steel, titanium, copper, and aluminum, making it a flexible option for various welding projects. The process also enables welding in numerous settings, supplying versatility in tough welding situations. Additionally, TIG welding generates welds with remarkable strength and integrity, making it a preferred selection for essential applications where weld quality is critical. Overall, the precision, versatility, and control used by TIG welding make it a beneficial method in the welding industry (Welding Inspection Service).

Advantages of Laser Welding

Another benefit of laser welding is its adaptability in collaborating with a wide variety of products, consisting of metals, plastics, and also dissimilar products. This versatility makes laser welding ideal for diverse markets such as vehicle, aerospace, electronics, and medical gadgets. The non-contact nature of laser welding additionally lessens contamination, making it a clean and eco-friendly welding method.

In addition, laser welding enables elaborate and intricate weld geometries that might be testing to achieve with standard welding strategies. This capability opens up new design More Help opportunities and enables the production of lighter and more innovative elements - Welding Inspection Service. Overall, the advantages of laser welding make it a recommended option for lots of manufacturing applications seeking high precision and effectiveness

Conclusion

Arc welding provides strong and resilient welds, while MIG welding supplies effectiveness and flexibility. TIG welding ensures clean and exact welds, and laser welding provides high accuracy and rate.

From the convenience of arc welding to the effectiveness of MIG welding, and the intricate work accomplished with TIG welding to the accuracy of laser welding, the variety of welding techniques available is huge. One typical type is MIG welding, additionally understood as Gas Steel Arc Welding (GMAW), which uses a wire electrode to sign up with steels with each other. Additionally, arc welding is known for its high welding speeds, which can dramatically enhance efficiency in producing procedures.With a focus on performance and longevity in welding processes, MIG welding presents a distinctive collection of advantages that complement the convenience and strength discovered in arc welding.TIG welding, likewise known as Gas Tungsten Arc Welding (GTAW), offers a distinctive collection of benefits that provide to precision and control in welding applications.

Richard "Little Hercules" Sandrak Then & Now!

Richard "Little Hercules" Sandrak Then & Now! Charlie Korsmo Then & Now!

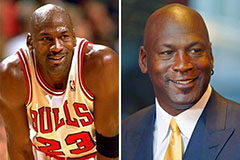

Charlie Korsmo Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Jane Carrey Then & Now!

Jane Carrey Then & Now! Megyn Kelly Then & Now!

Megyn Kelly Then & Now!